Thanks for all the great input, the LT250R owners are a good group of guys. You guys are buy far the nicest group of guys I have come in contact with on any ATV Forum.

We were shooting for a 80mm Bore. We thought 80mm would be achievable because we are planning on pushing the sleeve out and going back with nikisil plating. A nikisil plated Cylinder lets go of the heat much faster than a cylinder with a steel sleeve and cools much more efficiently. We planned on getting the cylinder to seal tight against the case deck by adding a aero-space titanium epoxy to the case deck to fill any and all imperfections and and having the deck milled to remove .012 as well as any unneeded additional epoxy. This will insure that the gasket surface is completely flat, then we had planned on using a thick .032 base gasket to make up for the material removed from the deck. My thinking was a thicker high quality base gasket w/ a thin coat of gasket spray would provide a good tight seal as long as all the hardware was torqued to 30-32 inch pounds and blue medium duty Permatex Loc-Tite Tape was was used to prevent anything from backing off over time.

I'm not sure if all this will work or not. I've come up with this idea and the 4mm Stroker Crank with 80mm bore by myself. I've only talked to the builder briefly about our plans and what I've found to be doable through the research I've done.

El Diablo machining the center cases and grafting a CP Power Valve Sphinx Setup on the LT250R Bottom end and using the TRX-250R Piston with a different rod sounds like a AWESOME idea! I bet buy the time we are done having the 86 RM 250 Cylinder modified, machined, nikisil plated and ported we'd have the same amount or maybe even more money tied up in it than we would on a CP Setup. I'm defiantly looking into that before we do anything.

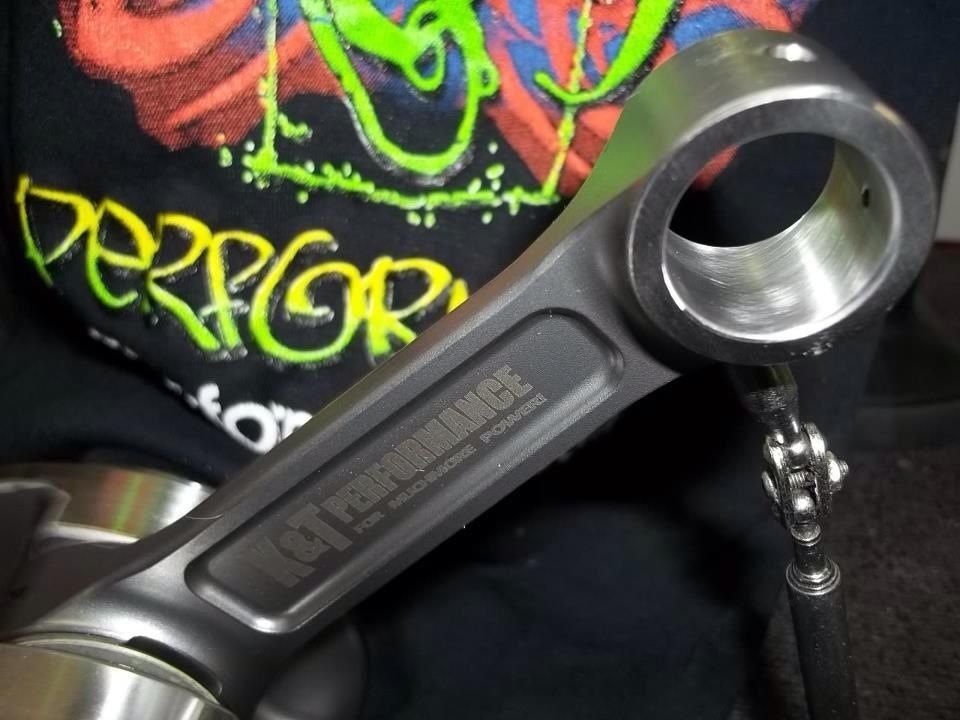

The Rod and Piston shouldn't be a problem because we figured we would end up having to get Wiseco to machine a custom piston for this application. I actually had Crank Work's custom machine and install 115mm Billet Rods for my Crank Work's 10 mil (64mm) Billet Stroker Crank I used with the 535cc Power Valve Cheetah Engine I had built for my Banshee.

If I remember correctly the custom billet rods were $225 or $235 per rod. So I'm assuming they will custom cut one the exact length we need for somewhere around that amount. Please keep the input coming I really appreciate it. El Diablo if you can send me a link to that TRX-250R CP Cylinder Swap Matt Shearer was working on that would be great!

Thanks again,